An injection robot is an advanced automated system widely used in industries such as injection molding, pharmaceuticals, food packaging, and electronics. By combining robotic arms, precision control systems, and programmable software, injection robots can inject liquids, adhesives, plastics, or other materials into designated containers or molds with high accuracy. They help manufacturers improve production efficiency, reduce human error, maintain consistent quality, and optimize safety in complex or hazardous operations.

What Is an Injection Robot?

An injection robot is essentially a robotic arm equipped with injection mechanisms, sensors, and a computer-controlled system. Unlike manual injection processes, it operates automatically according to programmed instructions. These robots can handle a wide variety of materials, including:

- Pharmaceutical liquids such as vaccines or injectable drugs.

- Food products like sauces, creams, or fillings.

- Industrial materials including plastics, adhesives, or epoxy for manufacturing components.

Modern injection robots are equipped with sensors and feedback loops that monitor each operation in real time, ensuring precision and preventing mistakes. This makes them indispensable in industries that require consistent quality, high hygiene standards, or delicate operations.

How Injection Robots Work

The operation of an injection robot generally involves three main stages:

- Programming and Material Preparation:Engineers input key parameters into the robot’s control system, including injection speed, volume, pressure, and target location. The robot also prepares the material, ensuring it is ready for injection. Some robots can automatically mix or heat materials to the correct consistency before starting.

- Injection Execution:Using sensors, cameras, or laser-guided systems, the robot identifies the exact injection site. The robotic arm then performs the injection according to the programmed parameters, delivering precise amounts of material with consistent speed and force. This stage is critical for maintaining product quality and minimizing waste.

- Quality Control and Feedback:Many modern injection robots include real-time monitoring systems that verify accuracy during the injection process. If a deviation occurs, the robot can automatically adjust its operation or alert operators to prevent defects. Some advanced systems even collect data for predictive maintenance and continuous process optimization.

Applications and Benefits of Injection Robots

Injection robots are used in a wide range of industries due to their efficiency, precision, and reliability:

- Pharmaceuticals:Injection robots ensure accurate dosing of drugs and vaccines, reducing the risk of human error and contamination. They can handle small volumes with extreme precision, perform repetitive injections consistently, and maintain strict hygiene standards required in medical production. This helps pharmaceutical companies comply with regulatory requirements while improving overall efficiency.

- Food Industry:In food processing, injection robots inject liquids, creams, sauces, or fillings into packaging containers with consistent portion sizes. They maintain hygiene by minimizing human contact, speed up high-volume production lines, and ensure uniform quality across batches. These robots can also handle delicate textures without damaging the product, which is crucial for items like chocolates or pastries.

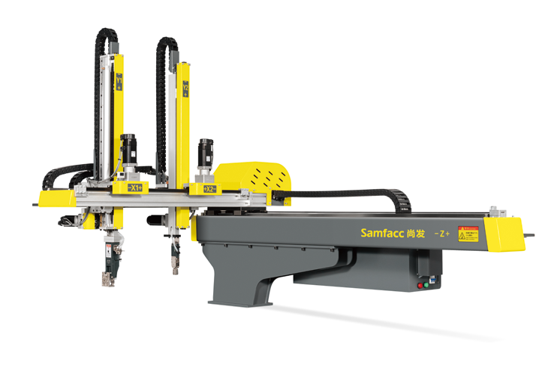

- Plastics Manufacturing:In injection molding, injection robots control the flow, pressure, and temperature of molten plastic, producing parts that meet precise design specifications. They can operate continuously in high-volume production, reduce material waste, and perform tasks such as removing molded parts from machines, trimming excess material, and assembling components with high accuracy.

- Electronics and Medical Devices:Injection robots are used to apply adhesives, encapsulate delicate components, or assemble miniature parts in electronics and medical devices. Their precision ensures proper alignment and bonding, reduces defects, and enables production of highly complex components that would be difficult or unsafe for human operators to handle.

The main advantages of injection robots include increased productivity, improved consistency, reduced human error, enhanced safety, and lower labor costs. By automating repetitive and precise tasks, they allow workers to focus on supervision, quality control, maintenance, and higher-level operations, ultimately improving overall operational efficiency and product reliability.

The Future of Injection Robots

With advances in artificial intelligence, machine learning, and IoT integration, injection robots are becoming smarter and more adaptive. Future robots will be able to automatically adjust to different materials and environmental conditions while providing real-time data analytics and predictive quality control. They will also work safely alongside human operators in collaborative environments and help reduce energy consumption and material waste for more sustainable production. These improvements will make injection robots even more valuable across industries, increasing efficiency, accuracy, and sustainability.

Conclusion

Injection robots are transforming industrial automation by providing precise and reliable injection solutions. They improve product consistency, reduce human error, and enhance safety by handling delicate or repetitive tasks. With advancing technology, these robots are becoming smarter and more adaptable, helping manufacturers optimize production and maintain high-quality standards across industries.